Blog

Hardline - The Ultimate Structural Test

28 July 2025 / Interview by Richard Cunynghame

The development of mountain bikes has been rapid and that is directly correlated to the challenges that riders have thrown at the bikes. Anyone that has been around a while, knows that they would definitely not be attempting most features in a bike park, if they were still on their late-90’s bike, simply out of the knowledge that the bike would not stay together, let alone be pushing to the limits that Red Bull Hardline dishes out. As riders demand more from bikes, design engineers and professional riders go to new levels.

With the worlds toughest downhill race on the doorstep of Atherton Bikes, it is only logical that Red Bull Hardline is considered an important testing ground by Atherton Bikes’ Head of Design Rob Gow.

“The key thing is just that it's the ultimate structural test. Through the race team and the build-up to the World Cup season we're developing the new bike, working with the athletes and Dave Weagle, building on all of the other bikes we've designed to date, tuning that in, that's the real finesse of the design in terms of getting the kinematic nailed.

Then really key is the stiffness, the relative front-rear end stiffness under different scenarios. The guys using the bike on the World Cup race circuit is one level of structural testing but because the riders are so skilled they actually ride so light in many ways that they're not necessarily giving the bike the hardest time imaginable, you know compared to a punter casing a jump for example. So getting them on it at Hardline ups the ante because the speeds and the forces are on such another level. It gives us that additional level of confidence that all of the analysis and engineering that we've done up front is right."

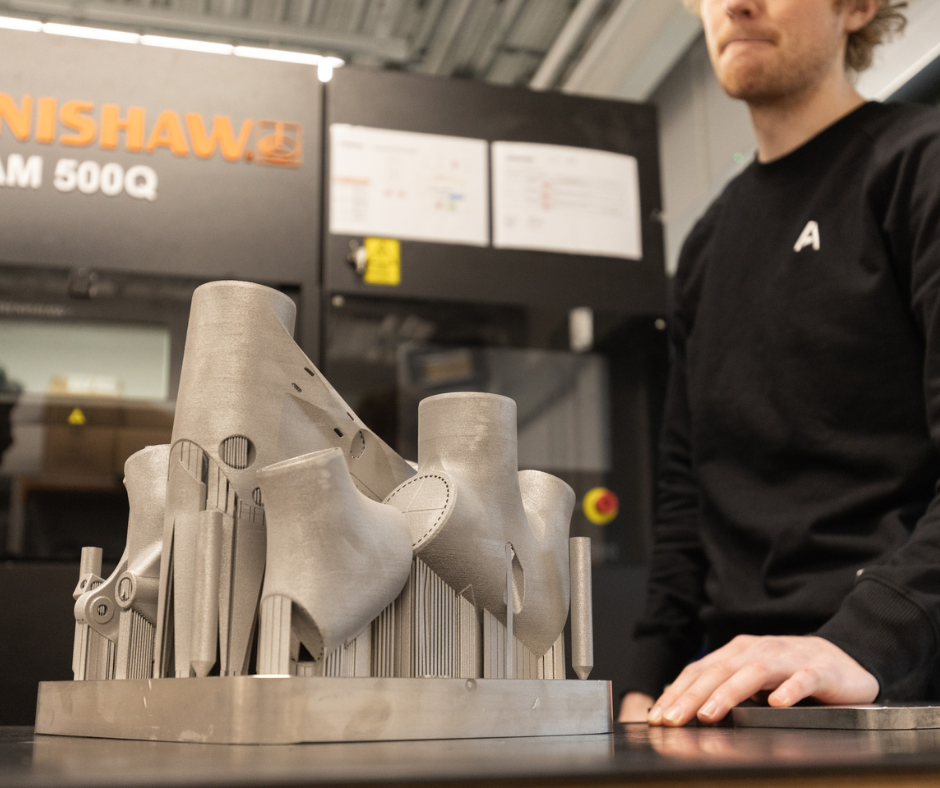

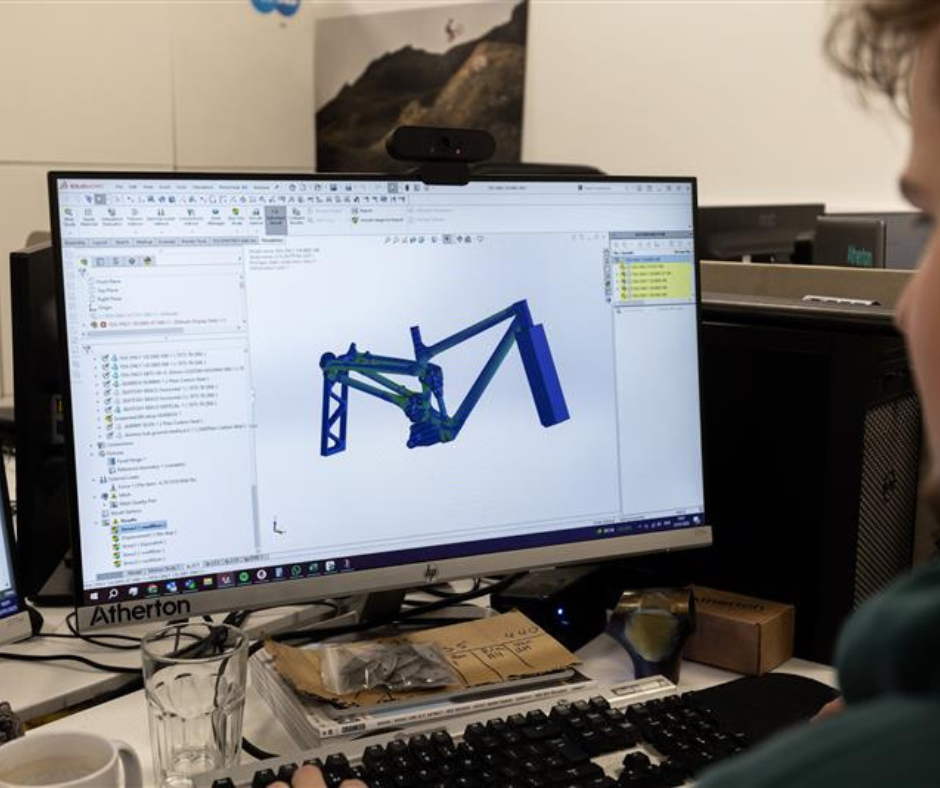

Obviously, when we're developing the bikes, we're doing virtual simulations of all the stresses. Finite Element Analysis (FEA) allows you to take a CAD model and apply forces to it that simulate what would happen on a track under different situations; that's your first level of checking.

We develop what you call a load case. That’s a specific situation where you say we're applying this level of force to this part of the bike. It's intended to simulate a certain situation. Over the time of Atherton Bikes evolution, we've developed a set of load cases that represent different scenarios. Whether it be landing a drop to flat or doing a flat corner, where you're introducing twisting torsional loads. For example, in one of them, you've got a heavy landing on a single pedal to a flat. You create these kinds of extreme worst-case scenarios that will put the nastiest types of forces and stresses through the frame.

“We've got another one where someone is landing seated, scenarios that would very rarely happen but they obviously do sometimes.

A seated landing at 8G, if someone actually did that they would obviously be in a terrible state but from the frame's point of view it's the worst case because force going through the seat post is quite different to force going through the pedals and the bottom bracket. You set the model up to basically simulate the forces both from the ground and from the rider going through the frame. You put in all the mechanical properties for the materials that are in the frame. It's very different simulating an aluminium frame from simulating a titanium and carbon frame because you've got different mechanical properties.

Then you let the computer do its thousands, hundreds of thousands of tiny calculations. The way it works is it converts your model into a series of tiny triangles, and then it works out the stress at each corner of those triangles and uses that to give you a representative real-world stress. You can then see where the hot spots are and where your stresses go above whatever limit you've set. Doing something on a theoretical basis, you're limited by all the assumptions you're putting in.

A downhill mountain biker travelling at World Cup pace is this hugely complex variable dynamic system, and you're trying to recreate that in a computer where you're creating a very un-dynamic moment, so the FEA is always limited in how much it can tell you. We don't take the results literally; it's more like it's painting a kind of blurry picture of what's going on, and then you have to interpret that and combine that information with the experience we all have as a team. We kind of build up this picture, and then we also combine that with lab testing.

Every day that bike is in the field being used and not breaking, it's reinforcing and giving us confidence in the simulations that we're doing. For seven years, we've been doing this for Atherton Bikes, and we have a high level of confidence in our simulation work because it's been proven out.

“Durability is one of our key pillars of integrity that the company's built on, so having the bikes ridden at Hardline whilst they're still prototypes is the ultimate final test pass. It's a real honour to have our products being ridden by riders of this calibre at the ultimate event. It's a huge privilege to be a part of what these guys are doing in this incredible sport, which is mind-boggling on every level.”