S.170 IS NOW AVAILABLE TO BUY ONLINE

March 19th, 2024

An affordable aluminium bike informed by our world-beating Additive Series.

From the day we launched in 2019 we’ve been committed to manufacturing a more affordable bike that would allow us to support grassroots riders like the people we ride with every weekend.

The S.170 is a hard-hitting, big-mountain enduro bike that builds upon the learnings from our Additive Manufacturing series. Strength and perfect-fit remain with 12 standard sizes on offer. The S170 has a mixed wheel configuration and 170mm rear travel with 180mm upfront and shares geometry with our award-winning A170. Dave Weagle’s DW6 suspension platform gives way to the simpler DW4 in keeping with the new model’s everyday, “chuck it in the van and go” vibe.

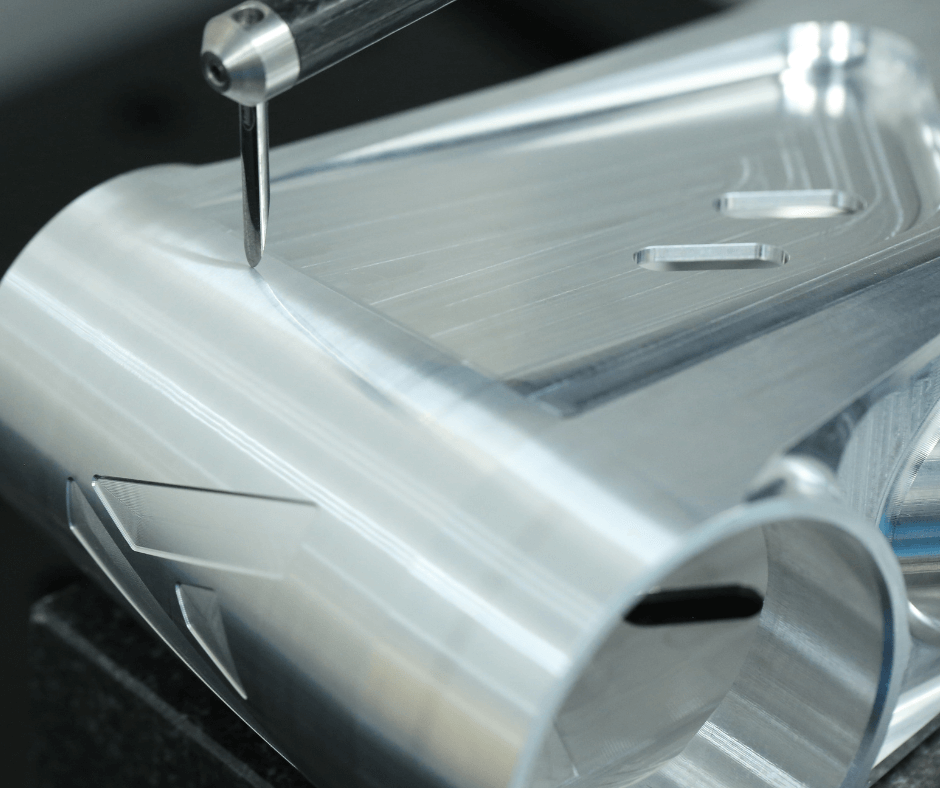

The S170 is constructed from Aluminium 7075 using subtractive manufacturing. Custom drawn 7075 aluminium tubes are joined to CNC manufactured lugs using our insanely strong double lap shear joints. Because we bond rather than weld our frames we can use 7075 Aluminium which has 70% higher fatigue performance and 70% higher ultimate tensile strength (UTS) compared to weldable alternatives (i.e. 6061 Aluminium).

The S170 will be available in limited numbers while we scale-up their production capacity.

2023 was a vintage year for us with World Championship Gold for Charlie (the first Elite Worlds’ medal for a British bike brand) and World Cup wins in Men’s and Women’s Elites for Andi and Rachel Atherton. The design freedom and speed of innovation associated with additive manufacturing means that we could apply valuable race learnings to the A170 and in turn to the new S170.

Gee Atherton said “We had to be as excited to ride this bike as our A170 and that’s a huge ask… The DW4 comes with the top-notch performance that our customers demand, and frame compliance and geometry are direct descendants of the A170 for that playful ride character that we love."

Dan Atherton said “I’ve put in a lot of hours on this bike and can say from experience that it’ll take everything you can throw at it. It’s made from a different material but we were determined that it would feel like an Atherton. We will only ever produce bikes that we’re proud to put our name on the downtube”

Head Designer Rob Gow said “There’s nothing radical in any of the separate elements of our new manufacturing process but we’ve brought them together in a genuinely unique combination. We’ve used established technologies but taken some innovative approaches only made possible by close collaboration with our technical partners. We knew we’d only discover our limits through the most rigorous testing, luckily we have the perfect testing location and the perfect testing crew…

Exhaustive testing in the field at Dyfi, Queenstown and more was followed by brutal testing in the lab. The S170 has passed EFBE Tri Test Cat 4 (Enduro) and Cat 5 (Downhill) meaning that we can offer a lifetime first-owner guarantee wherever you ride.

CEO Dan Brown said “Producing affordable bikes in the UK clearly has its challenges, especially for the design and production teams who were pushed to the edge on this one! But regardless of the drop-in unit price there will be no compromise on Quality Control. From the beginning of our brand this more affordable bike has been the dream, delivered with the same uncompromising attention to detail of the A-series. Although we’ll outsource some of the manufacturing processes, we will still bond all of the frames in-house in Machynlleth.

Fans of our A-series shouldn’t worry, it’s not going anywhere, in fact, we’re working hard to offer even more customisation options.”